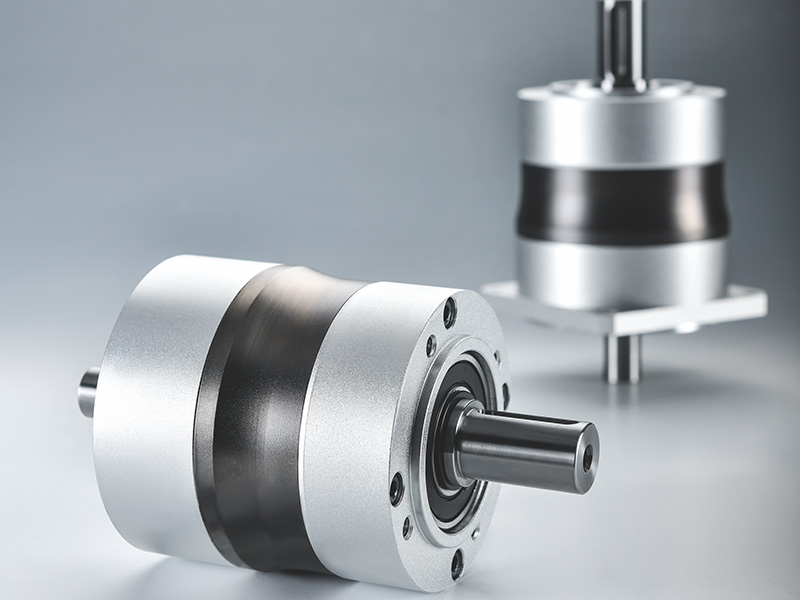

Before the planetary reducer is installed, confirm whether the motor and reducer are intact, and strictly check whether the size of the parts connected to the motor and the reducer match.

Before installation, clean the motor input shaft, positioning boss and reducer connection parts with gasoline or zinc-sodium water.

Before the motor is connected to the reducer, the motor shaft keyway must be perpendicular to the tightening bolt. To ensure uniform stress, first screw on the mounting bolts at any diagonal position, but do not tighten, then screw on the other two diagonal mounting positions, and finally tighten the four mounting bolts one by one.

The motor is naturally connected to the reducer. When connected, the concentricity of the reducer output shaft and the motor input shaft must be the same, and the flanges on the outside of the two must be parallel.

During the installation process, it is strictly prohibited to hit with a hammer, etc., and the bolts must be tightened before tightening the tightening bolts.

Remove the screws on the dust hole on the outside of the reducer flange, adjust the PCS system clamping ring so that the side hole is aligned with the dust hole, insert the inner hexagon and tighten. After that, remove the motor shaft key.

Tighten the tightening bolts. All tightening bolts must be fixed and inspected with the torque wrench according to the specified fixed torque data.

Reminder: The related data of the right-angle reducer is not exactly the same as the linear reducer of the same model. Please also pay attention to the user.