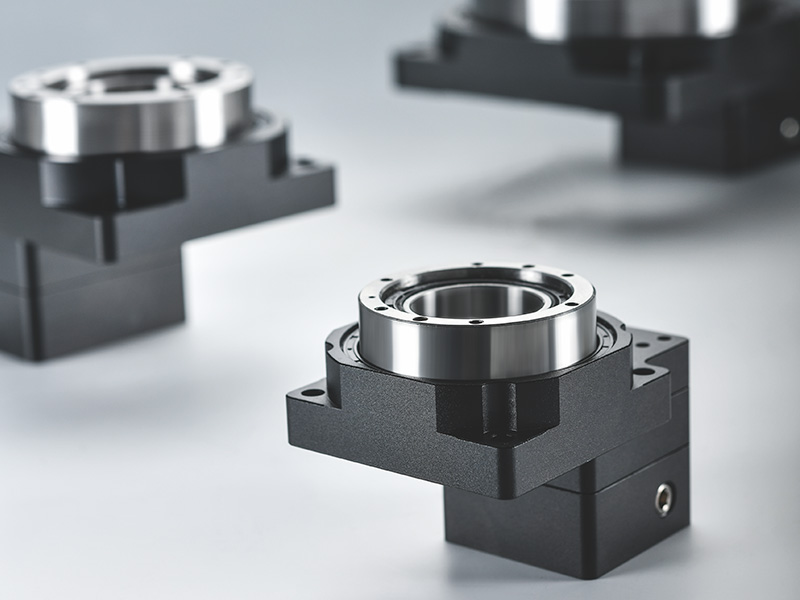

The main functions of the servo planetary reducer are stable rotation, low noise, strong rigidity and great power. Its parts are generally composed of planetary turret, planetary gears, bearings, ring gears, sun gear, sun gear seat, oil seal, flange, needle shaft, C-shaped buckle, breathable plug and so on.

The servo planetary reducer transmission structure can be divided into four parts: 1. Sun gear 2. Planetary gear 3. Internal gear ring 4. Stage gear. The drive source of the servo planetary reducer is directly connected to start the sun gear, and then the sun gear drives the planetary gear combined on the planetary gear carrier to run. The entire planetary gear system rotates automatically along the outer gear ring, and the planet carrier is connected to the rotating shaft output to achieve accelerated operation. If a higher reduction ratio is required, multiple sets of stage gears and planetary gears need to be operated together.

The deceleration characteristics of the servo planetary reducer can be divided into the following points: 1. High torque and impact resistance: The planetary gear mechanism is the same as the traditional parallel gear transmission method. Traditional gears only rely on the squeeze driving of a few point contact surfaces between two gears. All loads are concentrated on the few gear surfaces in contact with each other, which is easy to cause friction between gears and break. The planetary gear reducer has six larger areas with a 360-degree uniform load on the gear contact surface, and multiple gear surfaces uniformly withstand the instantaneous impact load, making it more able to withstand the impact of higher torque forces. The reducer and various bearing parts are also Will not stop working due to damage due to high load.

Small size and light gravity: Traditional reducers have multiple sets of gears that deviate from the staggered transmission. Because the reduction ratio must be generated by multiples of two gears, the gears must be engaged with each other at a certain distance, so the gearbox can accommodate space. It is relatively large, especially when it is a combination of high speed ratio, it is more necessary to connect the combination of two to three reduction gearboxes. Its structural strength is weakened, and the length of the gearbox is relatively long. This is likely to cause excessive volume and weight, which is not conducive to development demand. The structure of the planetary reducer can be repeatedly connected according to the required number of stages, or multiple stages can be combined individually.

The structure principle of the servo planetary reducer is mainly designed to meet the needs of work. Today, with the advancement of science and technology, the structure of the servo planetary reducer has also continued to innovate and develop, and it is developing in the direction of high efficiency, durability and simple structure.